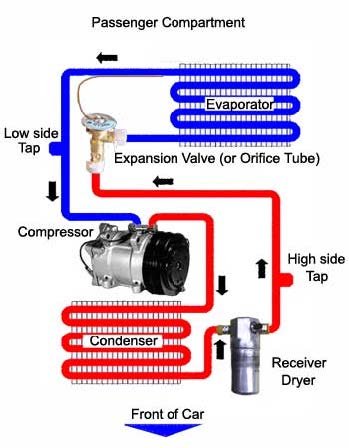

High/Low Pressure in the A/C System

In an automotive A/C system, the compressor is driven by a pulley on the engine's crankshaft. Since evaporation absorbs heat, and condensation releases it, the air conditioning system is designed to create pressure changes between the condenser and evaporator to aid in the cooling process. Refrigerant goes into the evaporator, where the hot air from inside the cabin is transferred into the refrigerant causing it to evaporate, and with it taking the heat from inside the vehicle. At the condenser, the refrigerant vapor has been compressed and forced through into the Condenser, turning into a liquid and releasing the heat previously absorbed from the evaporator.

|

High Side: This refers to the side of the system in red. The high side starts at the discharge side of the compressor travels through the condenser (Heat Transfer, condensation) the receiver drier and finishes at the expansion valve. The compressor creates high pressure by compressing the low pressure vapor from the evaporator so that the high pressure vapor can release heat at the condenser. The pressure change happens again at the expansion valve where the refrigerant is slowed down and changes pressure.

Low Side: This refers to the side of the system in blue. Starting at the expansion valve that exists to create low pressure. It travels to the evaporator where it transfers the heat from inside the vehicle and travels to the compressor where it is turned into high pressure and the whole process starts again. |

click "download file" to download pdf version

| gpd_tech_tip_29-how_it_works-high_low_pressure_in_ac_system.pdf |