How to Install Compressor Clutch

Without an Electric Clutch Plug

PLEASE NOTE:

gpd does not offer many clutch replacements. If the clutch is burnt out, the front seal is most

likely damaged and the compressor may leak and need to be replaced.

gpd does not offer many clutch replacements. If the clutch is burnt out, the front seal is most

likely damaged and the compressor may leak and need to be replaced.

Some compressor applications are designed without an electric clutch plug. To replace the compressor plug without an electric clutch plug, follow these steps:

* Always wear eye protection *

* Always disconnect the battery cables before working on vehicle *

TOOLS NEEDED:

* Always wear eye protection *

* Always disconnect the battery cables before working on vehicle *

TOOLS NEEDED:

- Wire Cutters

- Crimper (Recommended: Soldering Iron)

- Electrical Tape (Recommended: Heat Shrink)

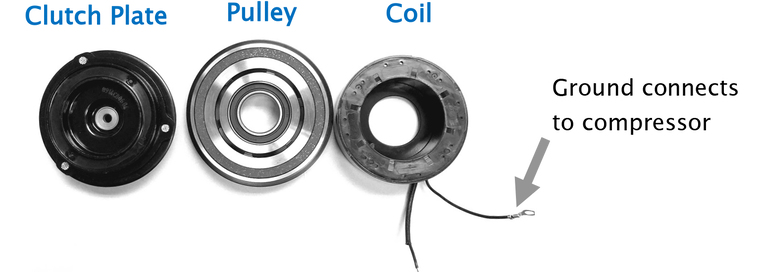

1. The clutch is made up of three interconnecting parts: Coil, Pulley, and Clutch Plate

|

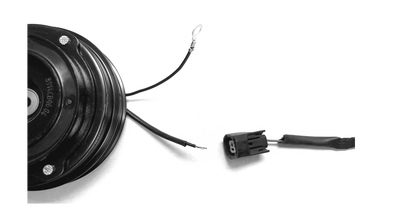

2. Assemble the clutch together and identify the power wire going to the vehicle’s power supply.

|

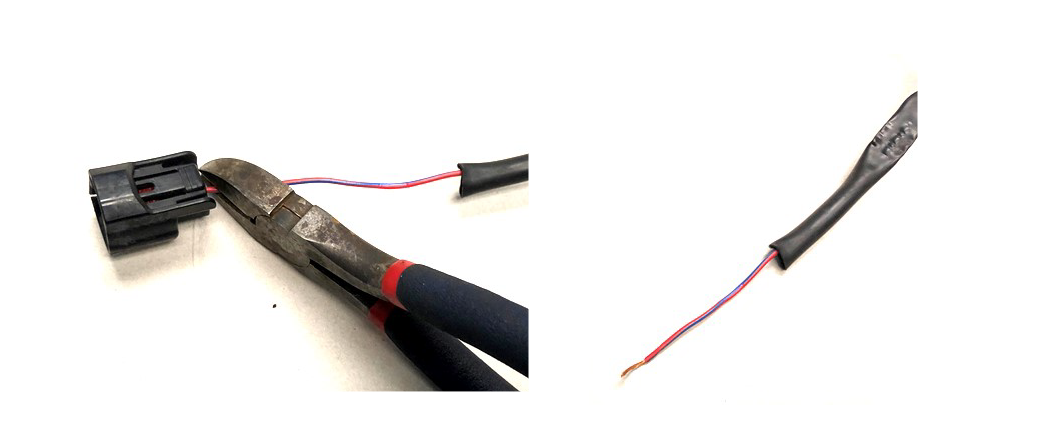

3. Cut the electrical connection from vehicle’s power supply and strip the protective coating back to expose the bare wire.

|

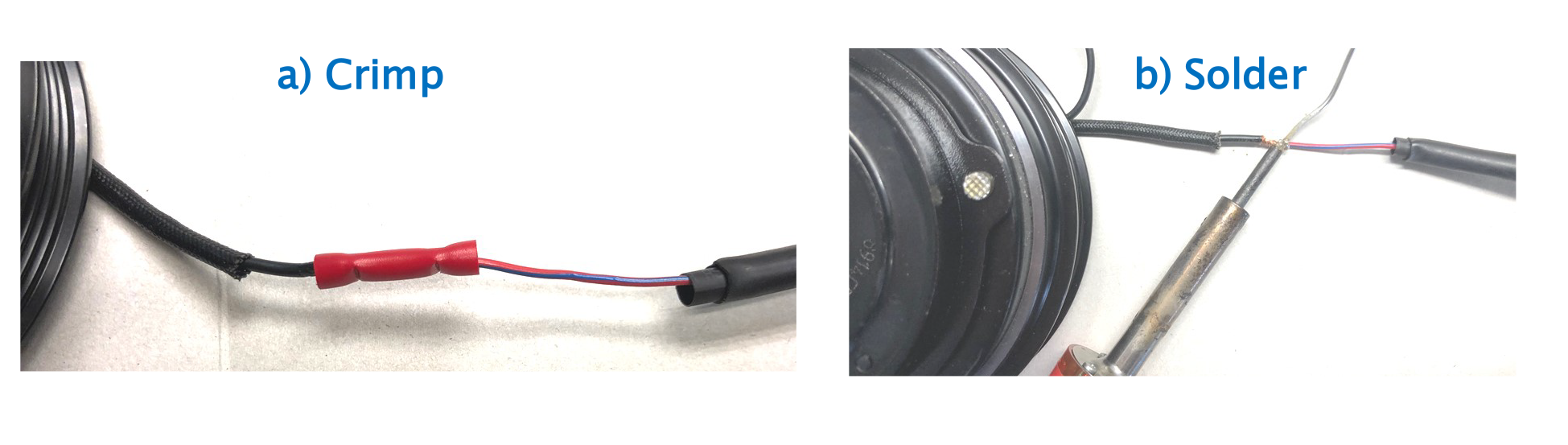

4. a) Use a crimper to connect wires or b) intertwine the two electrical wires and solder together.

5. Locate the earth strap, the eyelet connection attached to the compressor, where the last earth strap was located. Either tape or heat shrink the connection so it is watertight and cannot short out on another surface.

| gpd_tech_tip_129-compressor-clutch_installation_no_plug-how_to.pdf |