Alternator Decoupler Pulleys

An alternator decoupler pulley drives the alternator by transferring torque from the engine to the alternator via the belt. It powers the alternator during acceleration and cruising speed, and it disengages during engine deceleration. Its job is to reduce the drive system vibrations, improve the engine efficiency and increase the life of the belt, tensioner and other parts.

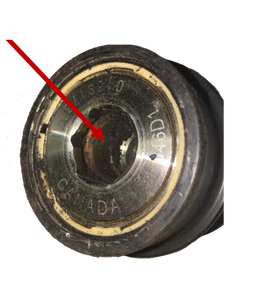

There are three types of alternator decoupler pulleys:

1. Solid Pulley

2. One Way Clutch Pulley

*This pulley will rotate freely in one direction but lock up in the other direction.

3. Overrunning Alternator Decoupler Pulley

*Contains patented spring to reduce belt noise, provide a smoother belt drive system and increase system durability.

These types of pulleys are not interchangeable and must be replaced with the correct pulley, or it will fail. The estimated life of the decoupler pulley is about the same as the belt and tensioner. It is best practice to replace the pulley, belt and tensioner all at the same time. A faulty decoupler pulley will add extra stress to the air conditioning compressor and may cause a premature failure.

When a decoupler pulley becomes worn, rusted, or filled with debris, it can cause a whiplash effect. This whiplash effect causes extra tension on the compressor pulley. Due to the extra tension, on the compressors pulley, the pulley can begin to shear and break free. When working on a compressor with a breakaway clutch, make sure to check the decoupler pulley, because this could be the reason for its failure.

There are three types of alternator decoupler pulleys:

1. Solid Pulley

2. One Way Clutch Pulley

*This pulley will rotate freely in one direction but lock up in the other direction.

3. Overrunning Alternator Decoupler Pulley

*Contains patented spring to reduce belt noise, provide a smoother belt drive system and increase system durability.

These types of pulleys are not interchangeable and must be replaced with the correct pulley, or it will fail. The estimated life of the decoupler pulley is about the same as the belt and tensioner. It is best practice to replace the pulley, belt and tensioner all at the same time. A faulty decoupler pulley will add extra stress to the air conditioning compressor and may cause a premature failure.

When a decoupler pulley becomes worn, rusted, or filled with debris, it can cause a whiplash effect. This whiplash effect causes extra tension on the compressor pulley. Due to the extra tension, on the compressors pulley, the pulley can begin to shear and break free. When working on a compressor with a breakaway clutch, make sure to check the decoupler pulley, because this could be the reason for its failure.

| gpd_tech_tip_73-alternator_decoupler_pulley-automotive_air_conditioning.pdf |