How to Measure Clutch: T/CCI (York Style)

If the part number on the clutch being replaced cannot be read, use the following procedure to determine the required clutch number.

1. Determine if 12 or 24 volt (Black Wire= 12V, Green Wire= 24V

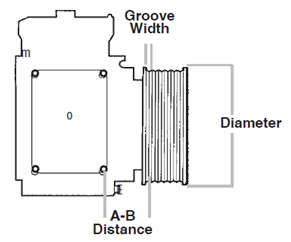

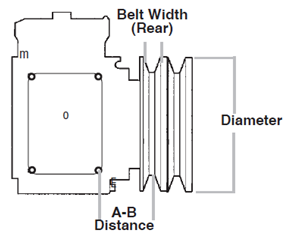

2. Determine if clutch is single, double, or poly groove.

3. Measure outside diameter of pulley.

4. Measure width of pulley groove:

a. Single and double groove= measure the width of pulley groove.

b. Poly groove= count the number of grooves.

5. Measure accurately the A-B distance:

a. Single and Double Groove= measure the distance from the compressor mounting hole on the side of the compressor to the middle of the

rear belt groove on the pulley (the rear belt groove is closest to the compressor).

b. Poly Groove= measure the distance from the compressor mounting hole on the side of the compressor to the middle of the first groove on the

pulley.

6. Determine the number of wires.

1. Determine if 12 or 24 volt (Black Wire= 12V, Green Wire= 24V

2. Determine if clutch is single, double, or poly groove.

3. Measure outside diameter of pulley.

4. Measure width of pulley groove:

a. Single and double groove= measure the width of pulley groove.

b. Poly groove= count the number of grooves.

5. Measure accurately the A-B distance:

a. Single and Double Groove= measure the distance from the compressor mounting hole on the side of the compressor to the middle of the

rear belt groove on the pulley (the rear belt groove is closest to the compressor).

b. Poly Groove= measure the distance from the compressor mounting hole on the side of the compressor to the middle of the first groove on the

pulley.

6. Determine the number of wires.

| gpd_tech_tip_80-compressor_clutch-tcci_york_style.pdf |