Replacing Parallel Flow Condensers when a Compressor Fails

|

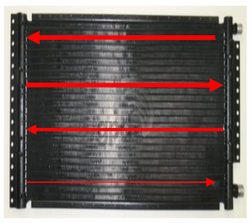

When a compressor fails the question for most technicians is whether to flush the condenser or replace it. For tube and fin condensers or serpentine condenser the choice is not difficult, the internal tube diameter is wide enough to be able to flush material through it to ensure the inside is clean and free of contaminants. On vehicles fitted with parallel flow condensers, usually around 1994 with the introduction of R134a, the choice is not as easy. The parallel flow condenser is a highly effective heat exchanger that divides the unit into sections or “passes” which creates a more efficient process for the refrigerant to change state from gas to liquid.

|

|

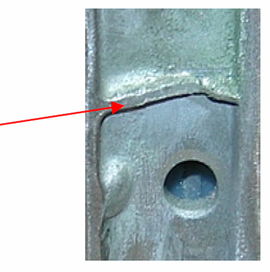

This is done by making the refrigerant change direction by 180° at the end on the side rails by placing a plug inside the rail at intervals, forcing the refrigerant change directions. The more plugs, the more times the refrigerant changes direction. In most condensers the refrigerant makes three to four “passes” through the condenser.

|

|

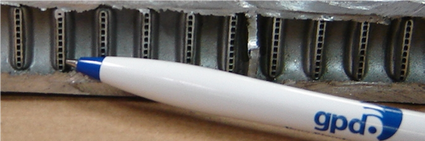

Parallel flow condensers don’t have a large hollow tube that the refrigerant flows through, but a series of very small tubes close together in a row with the internal diameter about the size of a pin head. This helps to improve the surface area of the condenser and increase its cooling capacity.

|

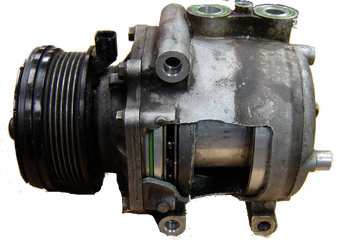

When a compressor fails it introduces contaminates into the system, one of the easiest ways to spot this is to remove the orifice tube that usually reveals metal deposits or sludge from a faulty compressor. The metal and sludge gets deposited throughout the system and will collect at places in the system with restrictions, like the orifice tube and on later model vehicles, the parallel flow condensers.

While flushing the system can help to remove debris from part of the system, items with small openings, like the parallel flow condenser are going to collect the debris. Flushing them will only push the contaminates further into the condenser and will collect at the plugs in the side rails, reducing the amount of rows available to cool the refrigerant and slowing the flow of the refrigerant, this leads to high head pressures. Combine it with a high efficiency compressor, like a scroll and not only will the replacement compressor fail, but it may be a catastrophic failure. |

When confronted with a compressor failure on a vehicle fitted with a parallel flow condenser, we recommend that the technician replace the accumulator, orifice tube or expansion device and condenser. We also recommend that all other components are flushed to ensure they are free of contaminates that could harm the new compressor.

| gpd_tech_tip_58-service_precaution-replace_condenser_when_compressor_fails.pdf |